| DESIGN

I was first intriguied by

the look of a Launch Pad Rockets

copy of the AS-17 "Krypton" and immediately

knew I wanted to upscale. First I needed to research the original

missile to assure myself of the dimensions needed and not just upscale

from the Launch Pad model. My only objective was to make the scale dependent

on a four inch diameter body tube.

I was not able to find scale

line drawings so I had to design from sizing and information both from

the Launch Pad version to scale up and scale down from what information

I could obtain on the web about the original Kh-31 missile.

I carefully measured the

parts from the Launch Pad Kit off the instructions and compared them to

Kh-31 dimensions found on the web. From these measurements I was able to

derive dimensions for my four inch diameter high power rocket scratch build.

The only dimensions of usefulness were diameter and length. Specific lengths

of ramjet and fins I had to upscale from the Launch Pad kit. In general

the scales I used were an approximate 1/3 scale of the original and 1.538

times the Launch Pad kit. After analyzing the ratio in RocSim I decided

it would be more flight worthy to extend the length. It is also more visually

appealing.

KRYPTONITE Construction Scale:

| Model |

Length |

Diameter |

| Launch Pad "Krypton" |

36.25" |

2.6 " |

|

|

|

| Kh-31 |

4.7 Meters (15.4 Feet) |

0.36 Meters (1.2 Feet) |

| Kh-31A |

4.7 Meters(15.4 Feet) |

0.36 Meters (1.2 Feet) |

| Kh-31P |

5.23 Meters (17.2 Feet) |

0.36 Meters (1.2 Feet) |

|

|

|

| "Kryptonite" 4" Sport Scale |

64.25" |

4.0" |

My only other clue to design

was from available photos of the missile.

SIMULATION

To make sure that Kyrptonite

would fly well, I had to first build the model in RocSim. i have measured

all parts of the Launch pad kit and using the supplied kit instruction

sheet, upscaled the placement dimensions of parts. The problem with RocSim

3.0 is designing tubular fins. I simply tried to add more parallel fins

to replicate the four tube surface area. In a later step I will weigh the

rocket to balance the real weight of the rocket in design simulation.

PIECES and PARTS

/ GLUE

Parts used in construction

of the Kryptonite:

| Nose Cone |

PML 3.9" long (16.25") |

| Payload |

LOC paper 3.9", 14" length |

| Body Tube |

LOC paper 3.9", 34" length |

| Fins |

3/16" birch 4 ply |

| Coupler |

(1) 6" LOC paper,(Altimer

bay) (1) 3" LOC Paper (tail support) |

| Motor Mount |

38mm LOC paper, 12" length |

| Centering Rings |

(2) 3.9" 3/16" plywood,

38mm |

| Motor Retention |

|

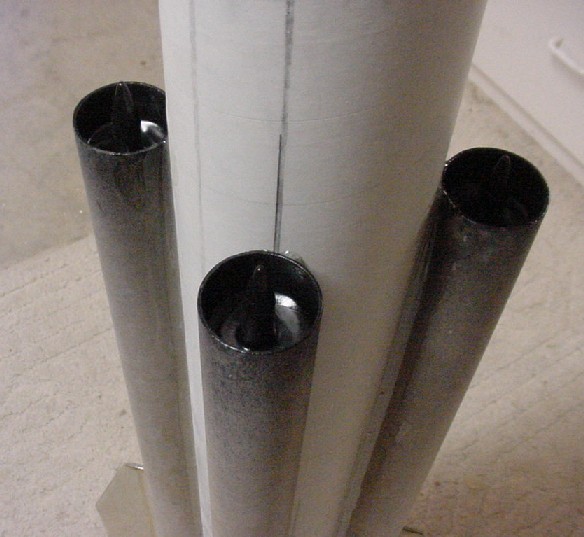

| Ramjets |

(4) 38mm paper tubes 25.25"

length,

(4) 1/8" 38mm bulkhead plates,

(4) 1/2" dowels, 2" length,

(4) Balsa tailcones hand

crafted |

| Shockcord |

(2) 1" tubular nylon 20'

w/loops; main chute and droge chute |

| Altimer Bay |

scratch built with (4) 3.9"

bulk head plates, 1/4" rods |

|

|

COMMING TOGETHER

The first construction activity

was the sizing and cutting of the outboard fins. I chose 3/16" 4

ply plywood for the fins as I am not as confident in shaping G10 fiberglass.

Also, there is not as much a weight difference between G10 and 3/16" ply

as with 1/4" plywood. Two sets of four fins are required on this

project, I simply copied the fin template from the Launch Pad "Krypton"

kit and allowed for the thickness of the ramjet tube, a 38mm paper tube.

I sanded the fins with a rounded edge and set them aside while I made a

12.25" hand slot cut in each of the ramjet tubes. Next I epoxied

the fin sets in the ramjet tube. (Fig.1 & Fig. 2). The creation of

the ramjet required hand shaping a point on the end of a 1/2"x2" dowel

and center mounting it on a 38mm x1/8" bulkhead plate with a small screw

and epoxy. The assembly was mounted 1" deep into the forward end of each

of the ramjet tubes. (Fig.3).

|

|

|

| Figure 1 |

Figure 2 |

Figure 3 |

The four ramjet tubes were

cross mounted 3.9" forward of the tail of the 34" body tube. Heavy epoxy

fillets were applied. Side fillets to create a smooth vertial sidewall

on the tubes were crafted using wood filler and Kliz paint. Several interations

of sanding, kliz, and sandable primer were applied. Tail cones were ordered

from Balsa Machine Service.

I ordered four BT-60/50 transition sections and hand sanded them to fit

the rear of the ramjet assembly. Again more sweat effort to kliz

and sand and sand and kliz to get a smooth finish.

Several tries of painting

the nose cone with light sanding and repeated paint and sand brings a great

smooth paint finish. Epoxied into the cone a 1/4"x 4" eyebolt. The

assembly seems sturdy, but will also loop kevlar thread into the bolt using

the normal cord attachment eyes holes on the cone.

I will attempt the color

scheme currently shown on the Boeing version , XM-31.

To be continued ...

|