| DESIGN

I was first intrigued by

the look of a Quest Rocket Aurora T3 when browsing the Net for just another

kit to build. Totally bored with big kits out of the bag - I look to the

challenge of an up-scale. Having failed miserably at a club launch in boost

glider competition - the Aurora T3 looked like a glider possibility. Not

long before I gave up the idea of glider competition - the upscale idea

hit.

The

kit was purchased from Value Land and

arrived in great shape like all their deliveries. I gotta say it

because everything is individually bubble wrapped. Inspection of

the kit showed all parts in the bag and whole. The

kit was purchased from Value Land and

arrived in great shape like all their deliveries. I gotta say it

because everything is individually bubble wrapped. Inspection of

the kit showed all parts in the bag and whole.

I went straight for the glider

parts to make sure this was do-able at the scale I wanted. I simply

laid out the laser cut balsa parts and traced them on graph paper.

Next I had Kelli at my work scan in the page and she factored it up for

the plotter. It was pretty much a 4:1 ratio coming in at 4.05% enlargement.

The upscale plotted dimensions work well with the available parts on the

market now.

For actual construction of

the rocket I generally plan to follow the kit instructions concerning dimensions

and placement of parts allowing for the upscale ratio.

SIMULATION

To make sure that upscale

Aurora 4.0 would fly well, I had to first build the model in RocSim.

I measured all parts of the Quest kit and using the supplied kit instruction

sheet, upscale the placement dimensions of parts. The problem with RocSim

3.0 is designing any parts to attach to the exterior much less design a

glider. I simply tried to add more parallel fins to replicate the surface

area of the glider. In a later construction step I will weigh the

rocket to balance the real weight of the rocket and the glider in design

simulation. A test throw of the glider will be necessary to trim

it for flight.

PIECES and PARTS

/ GLUE

Parts used in construction

of the Aurora 4.0:

BOOSTER

| Nose Cone |

LOC 3.9" |

| Payload |

None |

| Body Tube |

PML 3.9", 48"

length |

| Fins |

(3) 3/16" birch

4 ply |

| Motor Mount |

38 mm LOC paper, 17"

length |

| Centering Rings |

(3) 3.9" 3/16" plywood,

38mm |

| Motor Retention |

(2) 10/32" bolts,

T-nuts and screen clips |

| Shock cord |

(1) 1" tubular nylon

20' w/ loops |

| Recovery |

PML 54" round chute |

GLIDER

| Nose Cone |

BMS

BNC70AJ Alpha Classic |

| Body Tube |

LOC 54 mm, 24.3" length |

| Wings/ Stabilizers |

2 sheets popular 3/32"

12"x24" with

3/4 oz fiberglass

one layer |

| Bulkheads |

BMS

BT-70 Nose Blocks |

| Altimeter |

Olsen - M2,

400' main |

| Shock cord |

Tubular nylon 1/2"

10 foot |

| Recovery |

Top Flight 36" round

chute |

| Motor Can |

24 mm motor tube and

centering rings |

COMING TOGETHER

Glider Assembly

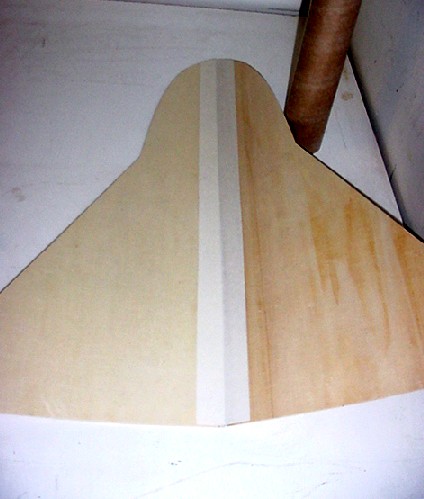

The first construction activity

was the sizing and cutting of the glider parts. I used 3/32" 12"x24"

popular sheets for the wing parts. Cutting the parts was easy using a utility

knife, straight edge and the template developed above. The nose cone

is balsa and I ordered it from Balsa

Machine Service. It is a BNC70AJ and fits a BT-70, sand the shoulder

lightly and it fits a 54 mm body tube. For added durability I lightly

coated the cone with finish epoxy and sanded. Figure 1.

My biggest fear was the wing

span of the glider not fitting on one sheet of material. As luck

would have it each wing fits the 4.0 ratio and works great with the 3/32"

12"x24" popular sheets available locally at MRS Hobbies. Carefully laying

out the templates I was able to use only two sheets for all the glider

wing parts. Test fitting the parts together revealed not stray edges. I

fretted in getting this joint right as the wings were slightly warped.

I had pressed the wings for a while and had to go for it. The best idea

was to use two sided fiberglass carpet tape. The tape would provide

an instant bond and hold while epoxy sets. Critical to the joint is also

the angle of the wings. A ten degree angle from plane for both wings was

necessary. Center the glider body tube and there you have the beginning

of the Aurora 4.0 glider. Figures 2 and 3.

Figure 4, shows the addition

of the top and bottom stabilizers. Before placing the bottom stabilizer,

I cut a groove, the width of the stabilizer, along the joint seam. Before

adding the bottom stabilizer I laid a single layer of 3/4 oz. fiberglass

and added the bottom stabilizer on top of the glass. This added just enough

rigidity to the wing surface to hopefully protect it in landing.

A layer of 3/4 oz. glass was also added to the bottom stabilizer.

|

|

|

|

Figure 1

Parts |

Figure 2

Glass tape joint |

Figure 3

Body Tube |

Figure 4

Glass bottom surface |

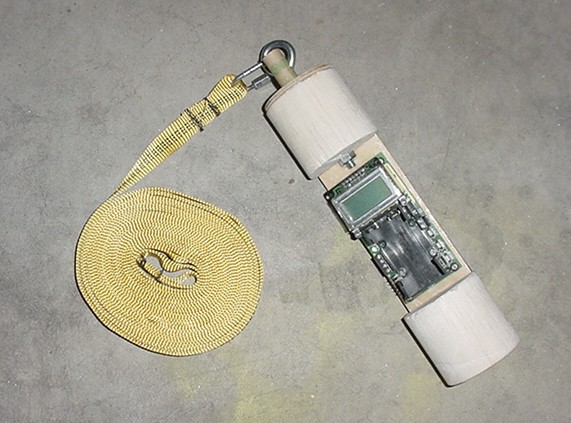

Packed inside the glider

will be an altimeter bay, recovery parachute and 24 mm motor mount.

Why all this if it is glider recovery? Well In the interest of public

safety - I am designing the glider for glide descent with an altimeter

controlled chute recovery during the final approach. Additionally

for balance and realism on the glider, I am adding a 24 mm motor mount

to hold an Aerotech 24/40 rms motor with just a delay charge. The delay

charge, ignited at apogee, will hopefully discharge tracking smoke to aid

in spotting the glider. Figure 5

Critical to the recovery

portion of the glider is the altimeter bay construction. To keep

weight down I halved a BT-70 balsa nose block from Balsa

Machine Service and crafted an altimeter mounting board in between.

Wiring tunnels were drilled forward and aft on the blocks to pass through

e-match leads from the the altimeter to ejection charge and delay charges.

The altimeter bay will be screwed into place inside the glider body tube

prior to launch. Figure 6.

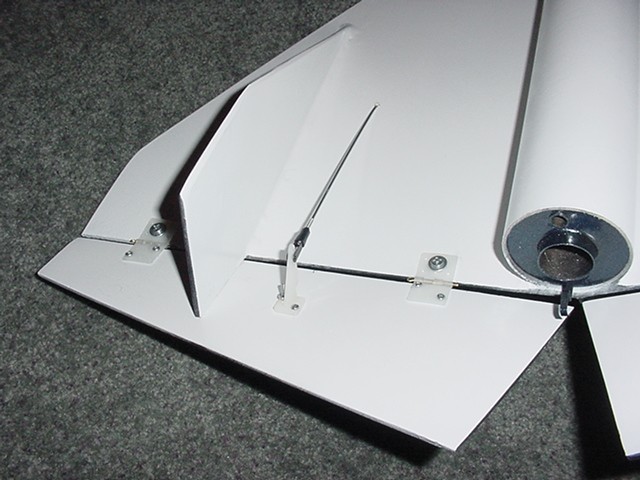

The most complicated construction

of the glider has been the attachment of the rear flaps. I toyed

with using the fiberglass tape again, however it is two sided and did not

want the upside sticky. After yet anther trip to MRS Hobbies, I obtained

aileron control tower, connector rods and wing hinges from the RC airplane

part selection. The intent is to have a sturdy flap that can be modified.

Figure 7.

|

|

|

Figure 5

Glider Rear |

Figure 6

Glider Altimeter

Bay |

Figure 7

Glider Flap Assembly |

Booster Assembly

Several tries of painting

the nose cone on the booster with light sanding and repeated paint and

sand brings a great smooth paint finish. Epoxied into the cone is

a 1/4"x 4" eyebolt. The assembly seems sturdy, but will also loop kevlar

thread into the bolt using the normal cord attachment eyes holes on the

cone.

The motor mount is a LOC

38 mm paper tube 17" in length. Three 3/16" plywood centering rings are

added to create the fin can assembly. A PML 3.9" diameter by 48"

length tube is utilized for the booster body. Ron Weigel at Rocky

Mountain Rocketry was the source for cutting the centering rings and

slotting the body tube. The fins are upscale from the Quest Aurora

kit pattern. I cut the fins from 3/16" plywood. One exception is

the outboard or center fin. I intentionally added 20% more surface

area to the fin to offset the glider surface area which would hang on the

opposing side of the booster. The intent is to equalize the drag and provide

best as possible vertical launch. A U bolt is added to the forward centering

ring for connection of a 24" bridle. The bridle is 1" tubular nylon cord

looped at both ends. A kevlar cord sheath will cover the bridle.

I made the bridle because I can't reach down the 4' body tube to connect

a reusable shock cord each time for flight. Figure 7. The body

of the booster is simple. No payload section - just fin can, body

tube and nose cone. Total length five feet. Figure 8.

|

|

Figure 7

Booster Fin Can |

Figure 8

Booster |

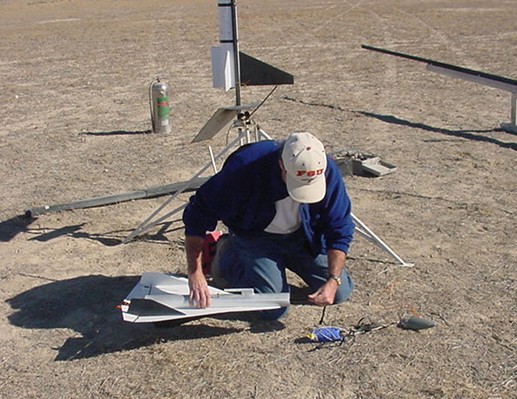

Final flight worthy construction

will be completed within hours of the beginning of the HellFire 7 Launch

September 14-16, 2001 hosted by the Utah Rocket Club, UROC.

FLIGHT

Planned flight will

be with a I-154J-6. It should loft to about 1,500' feet and detach the

glider at apogee. The booster will deploy only a main chute and return

under a 54" canopy. The altimeter on board the glider should fire

an e-match in the glider mounted motor casing to ignite an inverted Estes

D12-0 motor to create tracking smoke as the glider returns.. The glider

will trim out and at 150' deploy a 54" recovery chute to eliminate the

possibility of spectator or property damage.

Ready for flight at the October

2001 UROC launch.

Simple prep and load of

the motor and chute in the booster. The arming of the altimeter and final

chute packing of the glider has to be accomplished at the pad. Figure 9.

Double check the installation of the igniter wire and give the OK to launch.

Figure 10. Flight Ready Figure 11.

|

|

|

Figure 9

Arm Glider |

Figure 10

Launch Prep |

Figure 11

Flight Ready |

The actual flight was good

at lift off. The Aerotech I154J caused he lift off to be slow and easy.

The rocket rose and rotated over on the glider side. It continued

to climb and arc northwest. No delay charge was noticed at apogee

to pop the main chute or detach the glider. The D12-0 in the glider

did ignite and provide tracking smoke as the rocket AND glider nosed in.

The altimeter charge in the glider did blow and release the glider chute.

On the ground the main delay charge did blow. The motor 6 sec. delay

was more like a 12 sec.

Oh to rebuild - many discussions

were held as to a fix. Stay tuned.

|

Figure 12

Smoked Glider |

|